As I mentioned last time, after not working on the plane for a few months, it takes awhile to get back into the rhythm of it all. The fuselage doesn't start you out easy though; the first step is to cut metal away from the Center Section, which is probably the most expensive metal piece in the entire fuselage. I can't say for sure what it costs; it's not listed individually in the Van's price list like most of the other pieces are. Cost aside, now that I know of their scarcity after waiting months to receive it, I sure wouldn't want to damage it through carelessness. For that reason, I approached the countersinking of the eight holes called out in step one the way a minesweeper works his way through a mine field: one little bitty step at a time.

I general, I like countersinking. The end result is a nice machined look that exudes an aura of precision. Unless, of course, you dig too deep. Then it just exudes an aura of expensive scrap metal. The quota of profane words used to convey disappointment and disgust having already been spent during the tax preparation work of the earlier morning, I needed to be very, very careful in my cutting. I'd say it turned out well:

The holes that I countersunk in the picture above are the two little ones. Those four "pressed" dimples came that way - two similar holes will enter today's story a little later. Also note the etched part number and what I assume to be a serial number - the center section is a seriously critical piece and it wouldn't surprise me to learn that Van's tracks each and every one.

With the holes successfully countersunk, it should have been a simple matter to squeeze in the rivets and the nutplates they hold in place:

And it was. Except for one thing: that rivet just didn't look right when I was done. At first glance, it looked like I had used a universal head rivet (those are round on the top) instead of a flush rivet. It only took a second to realize why it looked that way: I hadn't changed the universal head die in the rivet squeezer with the flush die:

That was easily as frustrating and every bit my own fault as having filled out my city tax return, in ink, with the wrong city being paid. The tax return got torn up and redone. The rivet would have to be drilled out. Surprisingly, the depletion of my stock of choice words didn't bother me all that much and I just shrugged it off with no verbal outburst whatsoever.

First, I drilled down through the head using a bit two sizes smaller than the hole so I wouldn't risk enlarging the hole and thus ruin the precious center section:

The rivet hadn't been squeezed very tight since it was the first to be squeezed and I was therefore still trying to get the rivet squeezer set to the right gap, so I was able to punch out the rest of the rivet with a center punch:

For the next step, the center section gets set aside and we do a little work on a part that will eventually get attached to it. This step confused me for two reasons. First, the plastic Retainer Block gets attached to the F-1204CL-R, but there is no symmetric attachment of a Retainer Block to the F-1204CL-L. Asymmetry is, in my experience thus far, usually reason for concern. It means you're missing something. I scanned ahead in the plans but could find no step where the same task was applied to the left piece. The second cause for pause was that I was being instructed to final drill a hole into two countersunk holes in the part, which was odd enough, but then that countersinking was to be trapped and hidden between the retainer block and the part. That seemed a terrible waste of some very nice looking countersinking!

Sometimes you just have to swallow your doubts and press on; confusing things usually become clear eventually. In this case, my second concern was addressed almost immediately. When I put the called for #11 bit in the drill, I could see that using it to final drill the holes would completely "eat" the countersinking. Ah, the countersinking wasn't there to allow for a flush-mounted fastener, it was there to center the drill bit while the hole was being final drilled. It does beg the question as to why they didn't just drill the #11 hole for us, but that kind of question never does get answered. We just learn to live with those.

Having decided to press on, I clamped the part to the workbench, drilled the holes, and bolted on the retainer block:

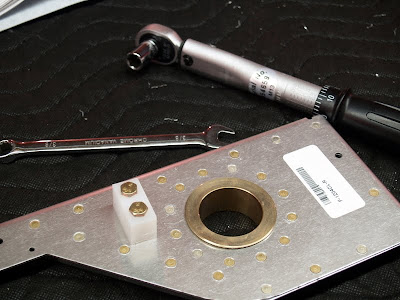

With the mystery of the asymmetrical retainer block hanging over me and darkening the mood in the room, it was with some degree of trepidation that I approached the next step, which was to exacerbate the mystery by asymmetrically installing a single retainer block in the center section. The holes for that block were also countersunk (although it might be more accurate to say "dimpled") to help hold the drill:

But, oddly enough, the same holes on the other side are filled with rivets:

While this doesn't explain why the left and the right sides are receiving unequal treatment in the realm of retainer blocks, it does send a strong indication that this imbalance is intentional. That's good enough for me! I went ahead with the drilling and the installing of the block:

There was only one more step on the page so I decided to go ahead and get it done. Unfortunately, it required retrieving a part from the shelves. That's a lot easier said than done early on when the vast majority of parts are still piled on the shelves rather than attached to the airplane, but I was able to locate the needed part fairly easily since it's relatively large. Basically this step was to dig out a couple of AN4 bolts to use as "locators" to get the part more or less in the right position on the center section and clamp it into place:

Looking at the long rows of undrilled holes, my guess was that I would soon see a step that required match drilling all of those holes to the center section.

And I was right! On the very next page, I'm offered the opportunity to drill 72 virgin holes, much like a [redacted - family blog]. To assist me in the performance of that step, the plans refer to a helpful tip on page 14-02. Great. That page comes with the wing kit which I don't expect to have until some time in August. I hope it wasn't a very important hint!